Enclosed vs Open 3D Printers: Proven Performance Comparison

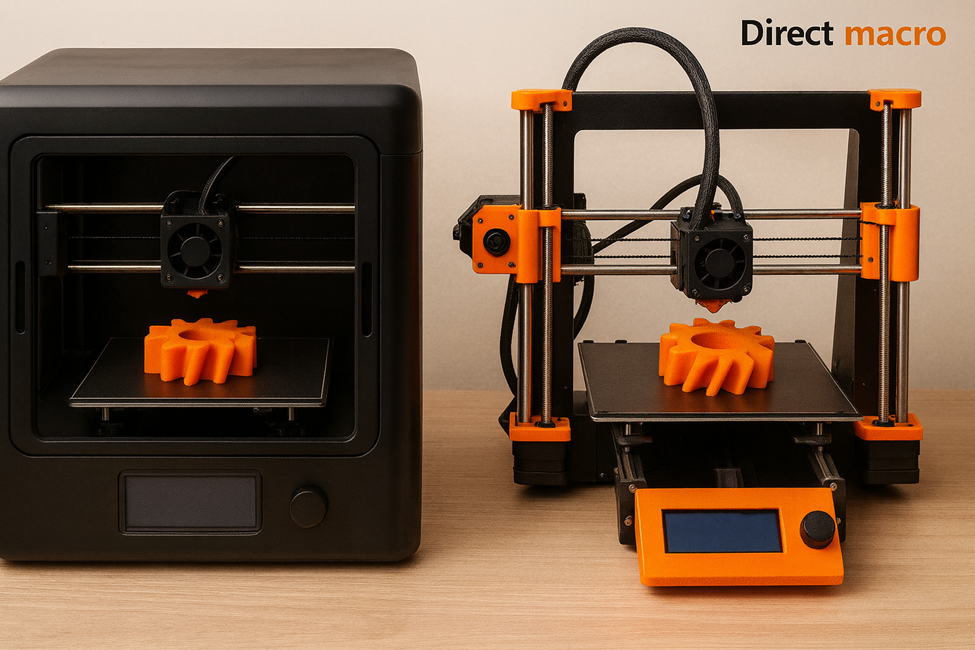

Introduction: The Core Difference in 3D Printer Design

There are many types of tools in the world of Fused Deposition Modeling (FDM) 3D printing, but one of the most important design decisions you will have to make is between an enclosed vs open frame model. This difference is not just about looks; it has a big effect on how well the printer works, what kinds of materials it can handle, and the entire experience of the user. For those starting out or looking to save money, choosing a reliable budget printer can provide a great introduction to 3D printing without compromising essential features.

The idea of environmental control is at the heart of the enclosed vs open 3D printers argument. As the name suggests, an open-frame printer leaves the build area open to the air around it, while an enclosed printer surrounds the build room with a protective shell. This difference in structure has a chain reaction of effects that range from print quality and the durability of the material to cost and safety. It is important to do a thorough comparison before making a purchase choice, especially when deciding between the best open vs enclosed 3D printer for your needs.

Understanding the Open Frame 3D Printer

The build platform and moving parts are visible and easily accessible in an open-frame 3D printer compared to an enclosed model. Most of the time, these styles have a simple metal frame (like an I3 or Cartesian style) and no walls around them. Just as selecting the right toner cartridge is crucial for print quality in traditional printers, choosing the right components and materials ensures reliable results in 3D printing.

Pros of an Open Frame Printer

Here are some pros of an open frame printer, you need to consider for making new purchase:

- Affordability: In terms of cost, they are much more reasonable. Because they do not have the extra panels and interior parts of an enclosure, they are easier to make and cost less. This makes them a popular choice for people who are just starting out. Similarly, portable printers offer an affordable and convenient solution for beginners and remote workers who need reliable printing on the go.

- Ease of Access and Maintenance: The open design gives you unmatched access to all of the parts. They are easy to fix problems with clogs, level the bed, do maintenance, and make changes or upgrades to. This makes them popular with hobbyists and people who like to experiment.

- Optimal for PLA: filaments like PLA and PETG, which need to cool quickly to get good detail, the open shape lets the most air flow through. This direct cooling helps keep layers from deforming and makes overhangs and bridges better.

- Visibility: Your view of the print in progress is clear, which helps you keep an eye on it and make changes as needed.

Cons of an Open Frame Printer

- Environmental Sensitivity: This is the most important problem. Drafts, air conditioning, and changes in room temperature can really damage the building area. When these things happen, prints can cool unevenly, which can cause problems like parts warping and layers breaking.

- Limited Material Compatibility: It is extremely hard to print on high-shrinkage, temperature-sensitive materials because you cannot control the temperature. This makes it very hard for them to use engineering-grade filaments like ABS, Nylon, Polycarbonate, and others with enclosed vs. open 3D printers for abs printing.

- Safety Concerns: Moving parts and hot components (such as the nozzle and heated bed) are exposed, providing a risk, particularly in areas with children or pets.

- Noise and Fumes: The open frame provides no sound dampening; hence these printers are substantially louder. Furthermore, any volatile organic compounds (VOCs) or disagreeable odors produced by materials such as ABS are directly released into the room.

Understanding the Enclosed 3D Printer

An enclosed printer has a protective, usually insulated, casing that entirely surrounds the print area. This design seeks to produce a more stable, controlled microenvironment. Choosing the right printer accessories, such as replacement nozzles, build plates, or maintenance kits, can further enhance the printer’s performance and longevity.

Pros of an Enclosed Printer

- Superior Temperature Stability: The core benefit: the enclosure retains heat from the heated bed and hot end, resulting in a continuous warm air temperature surrounding the part. This controlled atmosphere is critical when printing materials with high thermal expansion rates. Just as precise temperature control improves 3D prints, using a reliable scanner ensures that your documents and images are captured accurately and efficiently.

- Advanced Material Compatibility: A reliable enclosed vs open 3D printer for ABS printing, ASA, Nylon, and other high-performance or engineering filaments is almost always required. The steady temperature significantly decreases bending and cracking while improving layer adhesion.

- Enhanced Safety and Fume Management: The physical barrier keeps users safe from hot and moving components. More crucially, many enclosed models have air filtration (such as HEPA or activated carbon filters) or allow for external ventilation, which safely contains the fumes and particulates produced during printing.

- Noise Reduction: The enclosed walls function as a sound barrier, greatly lowering the noise from stepper motors and fans. It makes the printer more acceptable for home offices or shared workspaces.

- Dust Protection: The sealed chamber keeps dust, dirt, and drafts out of the sensitive printing process which results in more consistent prints and reduced machine maintenance.

Cons of an Enclosed Printer

- Higher Cost: The increased materials, complexity, and specialized components such as fans and filters result in a larger initial investment than their open-frame counterparts.

- Reduced Accessibility: Maintenance, troubleshooting, and removing a finished print all require opening a door or panel, making the procedure slightly more difficult than with an open frame.

- Potential PLA Issues: While ideal for high-temperature materials, the heated atmosphere can occasionally be too warm for PLA, resulting in ‘heat creep’ (filament softening too high up in the hot end) and clogs. Many enclosed printers address this issue by including adjustable ventilation or removable coverings.

- Less Customization: The engineered enclosure design can limit the space and ease of installing third-party modifications or large upgrades.

Performance Showdown: Enclosed vs Open Frame Printer Pros and Cons

To truly compare the two design philosophies, we need to look at specific performance metrics. The choice between an open frame 3d printer vs enclosed model often boils down to a fundamental trade-off between cost/accessibility and material capability/consistency.

1. Material Compatibility and Warping (Enclosed vs Open 3D Printer for ABS Printing)

The most critical factor for demanding materials is temperature control. Materials like ABS shrink significantly as they cool. In an open-frame printer, a slight breeze is enough to cause rapid, uneven cooling, stressing the print and leading to detachment (warping) or internal fracturing (cracking). For home enthusiasts looking to avoid these issues, choosing the best home printers with stable enclosures and precise temperature management can make a significant difference in print quality. For serious enclosed vs open 3d printer for ABS printing or engineering work, the enclosed model’s ability to maintain a consistent chamber temperature is a non-negotiable advantage that directly translates into a higher success rate and superior mechanical properties.

Quick Comparison

| Feature | Open Frame Printer | Enclosed Printer |

| Ideal Materials | PLA, PETG, TPU (Flexible) | ABS, ASA, Nylon, PC, Composites, PLA (with venting) |

| Warping/Cracking | High risk, especially with large parts or materials like ABS | Significantly reduced risk due to temperature control |

| ABS Reliability | Low; high probability of failed prints and poor layer adhesion | High; provides the stable, warm environment required for success |

2. Safety, Noise, and Environment

In any shared or indoor workspace, safety and environmental concerns elevate the enclosed printer to a superior position. The containment of noise and potentially harmful fumes (a key consideration when using a material like ABS) makes the enclosed design far more practical for long print jobs in a home, office, or classroom setting. Similarly, when managing inventory or shipping tasks, understanding the differences between a label printer vs barcode printer can help you choose the right device for your specific needs.

Quick Comparison

| Feature | Open Frame Printer | Enclosed Printer |

| Physical Safety | Low; exposed hot and moving parts | High; physical barrier for safety, ideal for shared spaces/schools |

| Fume Management | None; fumes/VOCs released directly into the air | High; often includes built-in filtration systems or easy vent ports |

| Noise Level | High; all motor and fan noise is audible | Low; the enclosure provides effective acoustic dampening |

3. Cost and Accessibility

Cost and accessibility are the two main factors to consider when making informed decision of new purchase of these 3D printers. Let’s compare both of them which one is more budget friendly and easy to go for maintenance and upgradability features.

Quick Comparison

| Feature | Open Frame Printer | Enclosed Printer |

| Initial Cost | Low (Budget-friendly) | High (Higher investment) |

| Maintenance | Easy; all parts are quickly accessible for repair and tinkering | More involved; requires opening/removing panels to access components |

| Upgradability | High; easy to add custom parts and modifications | Moderate; can be constrained by the fixed enclosure dimensions |

How to Choose the Right 3D Printer: Open vs Enclosed 3D Printer for Beginners and Pros

The choice between an enclosed vs open 3d printer is fundamentally driven by your budget, experience, and primary printing goals.

1. The Best Choice for Beginners

For users looking at the open vs enclosed 3d printer for beginners, the answer depends on their commitment.

- Choose Open Frame if:

Your budget is strictly limited, you plan to print only with PLA and PETG, and you enjoy tinkering with your machine. The low barrier to entry and ease of maintenance make the initial learning curve less intimidating.

- Choose Enclosed if:

You value consistency and safety over cost, and want a “plug-and-play” experience with a higher success rate right out of the box. An enclosed printer offers a more reliable process, reducing the variables a beginner has to manage, leading to fewer failed prints and less frustration.

2. The Best Choice for Professionals

- Choose Enclosed (or Active/Passive Chamber) if:

Your work requires functional prototypes, parts made from engineering materials (ABS, Nylon, PC), or you need high-volume, reliable, and repeatable production. Professionals prioritize the material versatility and print consistency that only an enclosed system can reliably provide.

- Choose Open Frame Only If:

You strictly print non-technical materials (PLA/PETG) and require the largest possible build volume for the lowest price, but be prepared to manage the environmental risks yourself.

Direct Macro – Our Top Selling Enclosed and Open 3D Printers

Discover our curated selection of top-selling 3D printers, perfect for professionals, hobbyists, and educators. These machines combine reliability and performance to bring your ideas to life.

Enclosed 3D Printer

1.MakerBot Replicator+ 1200 x 1200 dpi 55ppm 3D Printer

Experience faster, more reliable 3D printing with the MakerBot Replicator+, featuring a larger build volume and improved hardware for consistent performance and professional-quality models.

- Specifications

Features Fused Deposition Modeling (FDM) technology with a 29.5 x 19.5 x 16.5 cm build volume. It has a swappable Smart Extruder+, an on-board camera, and connectivity via Wi-Fi, USB, or Ethernet. The factory-levelled build plate has a “Grip Surface” for better adhesion. - Reasons To Buy

Engineered for reliable and consistent performance, it is considered user-friendly for professionals and educators. Its enclosed design and durability make it suitable for classroom or professional settings. - Reasons To Avoid

The printer is limited to using MakerBot’s proprietary filament and the build plate is not heated, which can limit material compatibility. It is also more expensive compared to competitors with similar features.

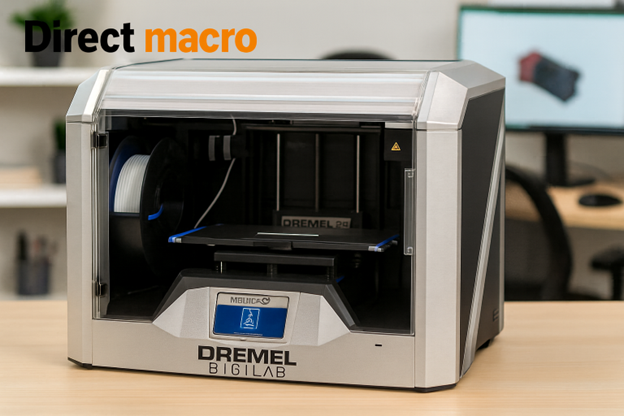

2. 3D40-FLX-01 – Dremel Digi Lab 3D40 Flex 3D Printer

Ideal for classrooms and beginners, the Dremel Digi Lab 3D40 Flex 3d printer offers reliable performance with an enclosed design, quiet operation, and an easy-to-use magnetic flexible build plate.

- Specifications

A fully enclosed FDM printer with a build volume of 25.4 x 15.2 x 17 cm (10 x 6 x 6.7 in) and a minimum layer resolution of 50 microns. It features a flexible, magnetic build plate, a 3.5-inch color touchscreen, and Wi-Fi connectivity. - Reasons To Buy

The printer is easy to set up and use, with a flexible build plate that simplifies removing prints. Its enclosed design and quiet operation are ideal for educational environments. It also comes with a cloud printing service and user-friendly software. - Reasons To Avoid

This model is limited to printing only with PLA filament, which restricts the range of possible projects. It does not have a camera for remote monitoring like some other Dremel models.

3.SKETCHKIT – MakerBot SKETCH 3D Printer

The MakerBot SKETCH is the ideal 3D printing solution for education, providing an easy-to-use, reliable, and safe platform with a heated build plate and integrated filters.

- Specifications

An enclosed FDM printer with a build volume of 150 x 150 x 150 mm. It includes a flexible heated build plate, a replaceable extruder, and a full-color touchscreen. Connectivity options include Wi-Fi, USB, and Ethernet, with an on-board camera for monitoring. - Reasons To Buy

It is designed for classroom use with safety features like an enclosed design and a particulate filter. The flexible heated build plate and automatic bed leveling make it easy to use for beginners and educators. - Reasons To Avoid

It has a smaller build volume compared to other options. Some users have noted a closed system that limits filament choices to MakerBot’s brand, making it less versatile for hobbyists.

Open Frame 3D Printer

Creality Printer CR-10 Smart FDM 3D Printer

The Creality CR-10 Smart FDM 3D printer is a smart and high-performance 3D printer, boasting a large build volume, remote Wi-Fi control, and intelligent auto-leveling for effortless and precise prints.

- Specifications

A FDM printer with a large build volume of 300 x 300 x 400 mm. It features silent stepper drivers, a 4.3-inch touchscreen, auto bed leveling, and Wi-Fi connectivity. It has a fixed heated bed with a removable glass surface. - Reasons To Buy

It offers a very large print volume at a competitive price and includes modern conveniences like silent drivers and auto-leveling. It also has a filament run-out sensor and a power-off resume function. - Reasons To Avoid

The printer’s firmware has been noted as buggy and may require updates. Some users have reported quality control issues upon delivery, and support for the product is limited.

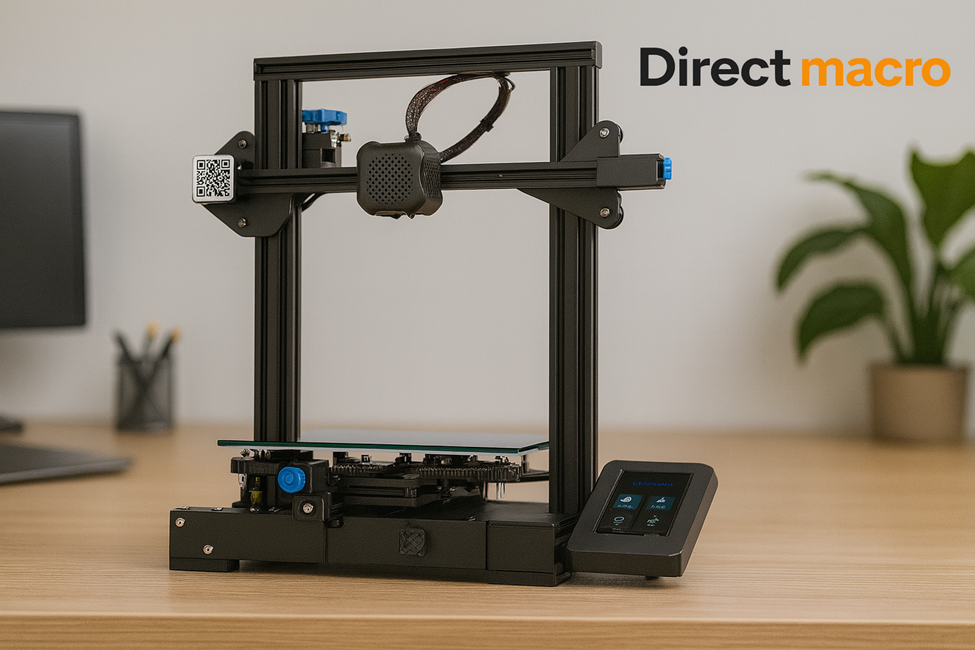

2.Creality Printer Ender-3V2 FDM 3D Printer

An enhanced version of a bestselling classic, the Creality Ender-3 V2 FDM 3D printer delivers silent operation, a new user interface, and upgraded components for a smoother and more reliable printing experience.

- Specifications

This FDM printer has a build volume of 220 x 220 x 250 mm. It is equipped with a 32-bit silent motherboard, a Carborundum glass platform, and a 4.3-inch color screen. The printer is an assembly kit and uses a Bowden extruder system. - Reasons To Buy

It is a budget-friendly and highly popular choice for beginners and hobbyists. The open-source nature and large community support make it easy to modify and upgrade. It is known for good print quality and a solid aluminum frame. - Reasons To Avoid

The printer requires manual bed leveling, and the assembly instructions can be difficult for some users. The stock plastic extruder is prone to cracking, and the cooling fans can be noisy.

3.Creality Printer Ender-3 S1 FDM 3D Printer

The Creality Printer Ender-3 S1 FDM 3D Printer offers exceptional out-of-the-box performance with its “Sprite” direct extruder, automatic leveling, and dual Z-axis, perfect for printing with a wide range of flexible filaments.

- Specifications

Features a “Sprite” direct-drive dual-gear extruder and a PC spring steel print sheet. It has a build volume of 220 x 220 x 270 mm, automatic bed leveling (CR-Touch), and a dual Z-axis for stability. The printer comes 96% pre-installed.

- Reasons To Buy

The direct-drive extruder allows for printing with a wider range of filaments, including flexible ones like TPU. Automatic bed leveling and a pre-assembled design make it easier to set up and use compared to its predecessors.

- Reasons To Avoid

Some users may find the non-touchscreen interface less intuitive, and the display’s beeping sound cannot be muted. The print speed is slightly lower than the Ender-3 V2 in some modes.

Final Thoughts: Making an Informed Decision

The debate of enclosed vs open 3d printers is not about one being definitively better than the other, but rather about matching the model to your goals. The open frame 3d printer vs enclosed comparison clearly shows that open systems dominate on affordability, accessibility, and simplicity (ideal for PLA and tinkering). In contrast, enclosed systems provide a critical advantage in performance consistency, material versatility, safety, and noise control.

If your primary goal is printing inexpensive prototypes with PLA or PETG and you operate on a tight budget, the open frame design is the best between open vs enclosed 3d printer for you.

However, if your projects require engineering materials, maximum print reliability, better safety and fume management, or you are looking at serious enclosed vs open 3d printer for ABS printing, the higher investment in an enclosed system is a necessity. By weighing the enclosed vs open frame printer pros and cons against your specific needs, you can confidently choose the 3D printer that will deliver the proven performance you require.

For more assistance, please call us at (855) 483-7810 or visit our request bulk quote page for bulk orders.

FAQs

- How does an enclosure affect maintenance and potential upgrades for a 3D printer?

With an open-frame printer, all components are exposed, making maintenance, cleaning, and modifications straightforward. On the other hand, accessing an enclosed printer’s components requires opening a door or panel, which can make routine tasks more cumbersome. When considering upgrades or repairs, the extra steps required for an enclosed model can be a factor. - What about the printing environment? Will an enclosed printer solve all my issues?

An enclosure significantly improves printing in environments with drafts or temperature fluctuations, but it’s not a complete fix for every environmental factor. For example, while an enclosure provides a buffer against external conditions, the internal temperature, especially with certain materials like PLA, can become too high and lead to heat creep or jamming. For this reason, some enclosed printers include ventilation systems. Additionally, humidity still needs to be controlled through other means, such as a dry box for your filament. - Is it possible to add an enclosure to an open-frame printer, and how effective are DIY options?

Yes, it is possible and quite common to add an enclosure to an open-frame printer. Many users build their own enclosures out of materials like acrylic or wood, or repurpose items like IKEA tables. These DIY solutions can be very effective at controlling temperature and containing fumes, but they must be constructed with fire safety and proper ventilation in mind, especially for filaments like ABS. A DIY enclosure is a great way to gain the benefits of an enclosed system without purchasing a new printer, but it does require some additional work.

Do you need advice on buying or selling hardware? Fill out the form and we will return.

Sales & Support

(855) 483-7810

We respond within 48 hours on all weekdays

Opening hours

Monday to thursday: 08.30-16.30

Friday: 08.30-15.30